SINGAPORE – By the mid-2030s, 92 trains on Singapore’s oldest and busiest MRT lines will be upgraded with new systems to detect problems early and reduce breakdowns, rail operator SMRT said on Dec 18.

The trains to get these advanced systems make up just under half the 198 trains on the North-South and East-West lines (NSEWL). Upgrades will also make train rides safer, smoother and more comfortable, SMRT added.

The first train to be upgraded in this manner – a fifth-generation C151B model in service since 2017 – has already been retrofitted by Chinese train manufacturer CRRC Sifang.

It was returned to Singapore for testing in October, and will undergo further tests until May 2026 before entering passenger service in June that year.

The train will serve as proof-of-concept to test the new systems, which will be installed in other fourth-, fifth- and sixth-generation trains if they perform as intended. Upgrades are typically carried out when trains are about 15 years old.

Of the 92 trains, 35 are fourth-generation, 45 are fifth-generation and 12 are sixth-generation.

The rest of the fleet is made up of the newest seventh-generation trains, 78 of which are currently in service, while another 28 are pending arrival or undergoing testing.

Fourth-generation trains have been in service since 2011, while sixth-generation trains have been in service since 2018. The first seventh-generation trains entered service in 2023.

The upgraded train also features enhanced air-conditioning and ventilation systems to improve passenger comfort and energy efficiency, SMRT said.

A SMRT staff demonstrating the use of a bore scope to detect wear and tear on the rubber of the train door’s roller at SMRT Bishan Depot.

ST PHOTO: KEVIN LIM

New sensors embedded in the train help engineers detect potential issues before they turn into faults, said Mr Andy Chiang, managing director of STRIDES Technologies, SMRT’s innovation and engineering hub.

“These timely alerts enhance rail reliability and deliver more comfortable journeys for everyone,” he said.

New condition monitoring systems track the health of key components to enable predictive maintenance, while structural health monitoring systems continuously monitor the train’s structural integrity.

Together, these technologies aim to reduce breakdowns and improve safety, SMRT said.

The upgrade has added about 180 new sensors to the train, on top of the 300 already installed. Most are installed in hard-to-access areas such as the train’s undercarriage and are not visible to commuters. The aim is to intervene early, before faults lead to delays or damage.

The first proof-of-concept train was previewed by the media on Dec 18 at Bishan Depot, where journalists were given a ride on a test track within the depot.

Such systems were not present on a first-generation train that caused

a major six-day breakdown on the East-West Line in September 2024.

That train was part of the first-generation Kawasaki Heavy Industries fleet, and has since been replaced. The disruption was one of the worst in Singapore’s rail history, and SMRT was fined $2.4 million by the Land Transport Authority.

The upgraded trains are now even more technologically advanced than the seventh-generation models currently in service.

One key feature of the proof-of-concept train is a new condition monitoring system, which detects potential problems early to keep trains running smoothly.

The system currently tracks 47 indicators that may develop into faults, such as the door mechanism and electrical components, with more indicators to be added as testing continues.

With the added sensors, engineers can monitor and adjust air-conditioning temperatures in each train car remotely.

The system continuously checks critical components including power supply, air-conditioning, doors and brakes, runs automatic diagnostics, and uses predictive algorithms to assess the train’s condition.

Real-time data is transmitted to the relevant teams, allowing maintenance staff to track and respond to potential issues.

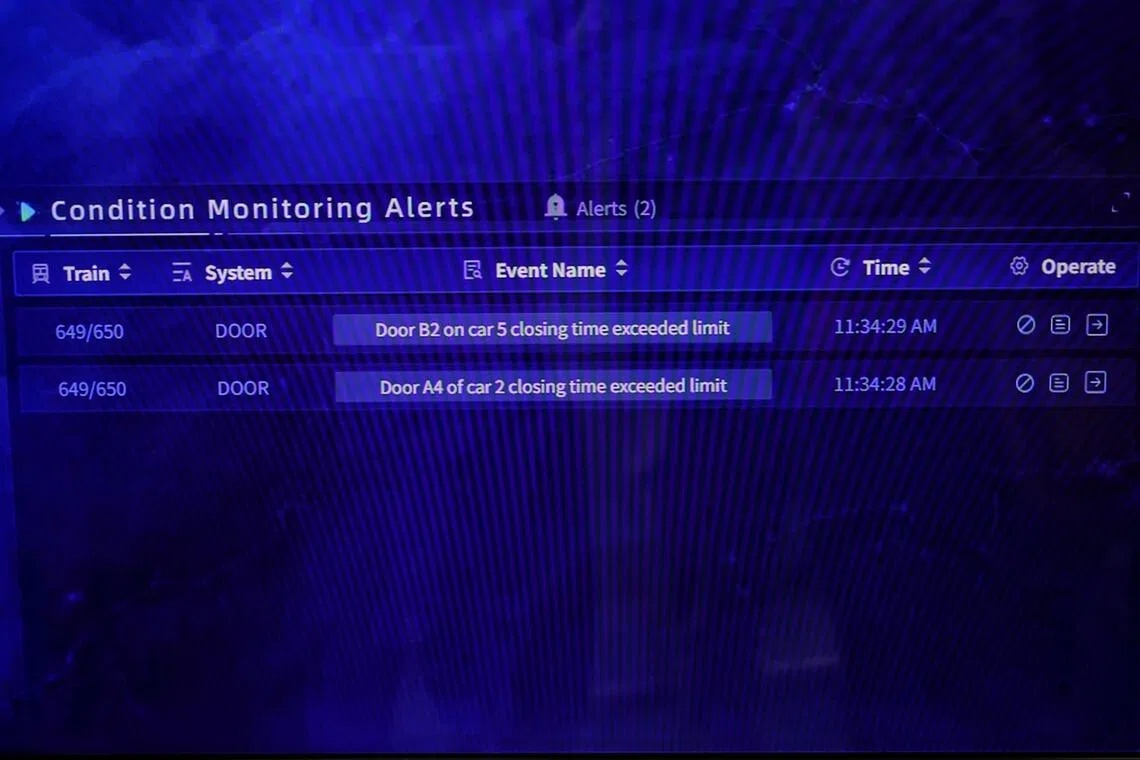

Demonstration of slow closing train doors with monitoring alerts shown on screen during a media preview at SMRT Bishan Depot.

ST PHOTO: KEVIN LIM

Previously, faults were only flagged after a component failed. The new system adds early detection, identifying wear or malfunctions before they escalate.

During a media ride on Dec 18, engineers simulated a door fault. Passengers noticed nothing, but the system detected that the door had closed milliseconds slower than normal. It also pinpointed the exact door needing inspection, rather than just the carriage, saving time and manpower.

Another upgrade is the structural health monitoring system, which continuously checks the train’s structural components, including car bodies and bogies, which refer to the undercarriage of a train.

Demonstration of slow closing train doors with monitoring alerts shown on screen during a media preview on Dec 18.

ST PHOTO: KEVIN LIM

By tracking minor stress, strain and vibration changes, the system allows maintenance staff to intervene earlier, lowering the risk of unexpected issues and supporting long-term fleet reliability.

The train has a new energy-efficient air-conditioning system, with sensors that detect issues early, and design improvements reduce breakdowns and leaks, keeping passengers cooler.

Additionally, a bogie monitoring system tracks the undercarriage, including wheels, axles, suspension and gearboxes. Temperature and vibration sensors combined with smart algorithms detect wear or degradation early, supporting predictive maintenance and minimising downtime.

SMRT said these technologies collectively track potential issues across the train’s critical components, and will boost reliability and commuter comfort across the fleet.

The operator is also studying the Circle Line (CCL) trains, some of which have been in service since 2009, to decide whether to introduce new trains or upgrade the existing ones.